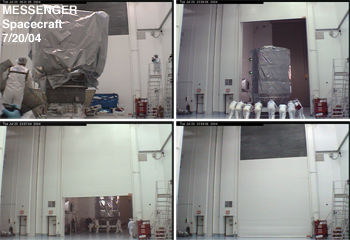

Going, Going, Gone! (July 27, 2004)

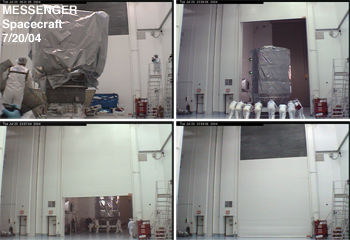

MESSENGER is now sitting atop the Boeing Delta II launch vehicle at Cape Canaveral Air Force Station's Space Launch Complex 17. This set of Webcam images takes you through MESSENGER's final moments at the Astrotech Space Operations Facility, where the team had been processing and testing the Mercury-bound spacecraft since March.

At upper left, with MESSENGER wrapped in two sheets of protective plastic, members of the Boeing team install a section of the “can” that protects the spacecraft and the attached, third stage of the launch vehicle during transport. Four sections are assembled around the base of the third stage; the rest of the can fits over the spacecraft in one piece. The 15-foot-tall can itself was then double bagged for additional protection.

After the team rolled MESSENGER out the door - seen in the next three images - the spacecraft made the 22-mile trip to the launch pad, crawling at 5 miles an hour atop at four-wheeled transporter. The top protective bag around the can was removed once the spacecraft arrived at the launch pad; the other came off once the team sealed the clean room that encloses the spacecraft on top of the launch vehicle.

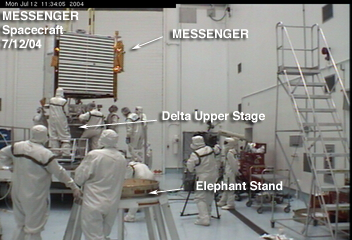

Next Stop: The Launch Pad (July 19, 2004)

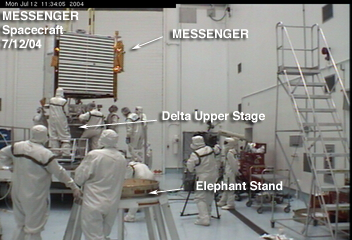

The MESSENGER spacecraft is now firmly attached to the third stage of its Delta II launch vehicle. In this Webcam view from July 12, the spacecraft is being carefully lowered onto the Delta's third stage, in anticipation of the launch period that opens at 2:16 a.m. (EDT) on August 2. MESSENGER is attached to the rocket with a two-piece clamp band (also known as a Marmon clamp) and will detach when the spacecraft is launched and on the way to its first planetary flyby.

The Delta II 7925-H (heavy lift) model is the largest allowed for NASA Discovery-class missions. It features a liquid-fueled first stage with nine strap-on solid boosters, a second-stage liquid-fueled engine and a third-stage solid-fuel rocket. With a propellant made mainly of ammonium perchlorate, the third stage provides the final boost (nearly 15,000 pounds of thrust) that sends MESSENGER into its heliocentric (Sun-centered) orbit - and on track to return to Earth for a flyby next summer. After the rocket's fuel is spent, a pyrotechnic “bolt cutter” drives a blade through the 5/16-inch diameter bolts that secure the clamp band, releasing the spacecraft.

The next major activity is the encapsulation of the spacecraft and third stage in a “can” for the 22-mile trip to the launch site on a wheeled transporter. Because the transporter must make the journey at only 5 miles per hour, the trip will be done at night when roads can be closed. When the transporter arrives at the launch pad, the can will be hoisted to the top and the third stage and spacecraft assembly will be attached to the top of the Delta II rocket.

Click below for short time-lapse movies of the “mating” to the third stage:

Fill 'er Up! (July 9, 2004)

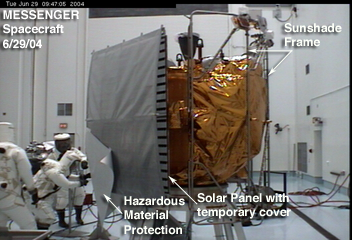

MESSENGER is nearly ready to head to the launch pad. Last week the engineering team loaded propellant - the fuel and oxidizer needed for MESSENGER's thrusters - into the spacecraft. This week's Webcam image shows the team loading the oxidizer (nitrogen tetroxide); a few days later they loaded the hydrazine fuel.

When the oxidizer and fuel mix they spontaneously combust, eliminating the need for any complicated spark mechanism on the spacecraft. The volatile nature of these materials and their high toxicity necessitates extreme care; here the MESSENGER team members wear special anti-contamination suits to ensure their safety. These suits are sealed and have their own air supply.

Each of MESSENGER's three main tanks - 22 inches in diameter and 41 inches long - can hold up to 53 gallons of propellant. As with all spacecraft components mass is at a premium, so the custom-designed tanks are made of lightweight-yet-strong titanium. In some places, the tanks' walls are just 0.02 inches thick.

At launch the spacecraft will have approximately 97 gallons of hydrazine - with about 47 gallons in two of the main propellant tanks and just less than 3 gallons in an auxiliary tank. The third main tank holds about 42 gallons of oxidizer. And the next time you think you're being pinched at the pumps of your local gas station, consider this: a gallon of nitrogen tetroxide costs $224, while the same amount of hydrazine costs $630.

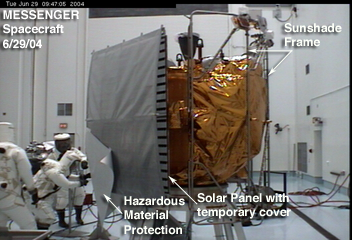

Upon Reflection... (July 2, 2004)

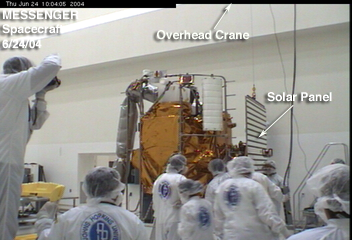

MESSENGER will rely on solar panels for power during its long voyage to and orbit around Mercury. The custom-developed panels, installed on the spacecraft June 24-25, were the next-to-last major components to be attached before the spacecraft is moved to the Delta II launch vehicle this month.

To run MESSENGER's systems and charge its 23-ampere-hour nickel hydrogen battery, the panels, each about 1.5 meters (5 feet) by 1.65 meters (5.5 feet), will support between 385-485 watts of spacecraft load power during the cruise to Mercury and 640 watts during the science orbit. The panels could produce more than two kilowatts of power near Mercury, but to prevent stress on MESSENGER's electronics, onboard power processors take in only what the spacecraft actually needs.

The panels are 67 percent mirrors (called optical solar reflectors) and 33 percent triple-junction solar cells, which convert 28 percent of the sunlight hitting them into electricity. Each panel has two rows of mirrors for every row of cells; a total of 648 cells and 1,296 mirrors per panel. The small mirrors reflect the Sun's energy and keep the panel cooler. The panels also rotate, so MESSENGER's flight computer will tilt the panels away from the Sun, positioning them to get the required power while maintaining a normal surface operating temperature of about 150 degrees Celsius, or 302 degrees Fahrenheit.

Major events before moving the spacecraft include fueling - the team is loading the hydrazine fuel and nitrogen tetroxide oxidizer this week - and final installation of the sunshade.

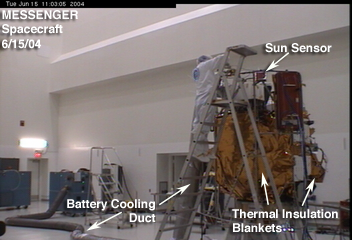

Closing Out (June 22, 2004)

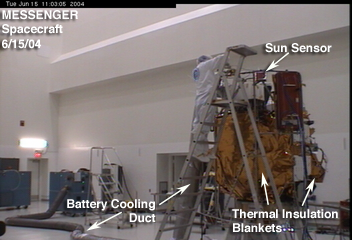

The MESSENGER team is starting final closeout of the spacecraft in preparation for launch. In this Webcam frame an engineer applies silver Teflon tape to the X-Ray Spectrometer's solar monitor. After the tape was applied, the thermal insulation blanket was tucked in around its edges in its flight configuration.

The X-Ray Spectrometer (XRS) solar monitor is a simple device, yet it will play a critical role during the orbital phase of the mission. The main XRS instrument measures how solar X-rays interact with Mercury's surface, allowing scientists to estimate the abundances of elements such as magnesium, aluminum, silicon, sulfur, calcium, titanium and iron. Accurate measurements of these elements require knowledge of the intensity of X-rays hitting the surface - the solar monitor measures the X-ray intensity hitting the Sun-facing side of the spacecraft, “knowing” the planet will receive the same intensity. (Don't confuse the XRS solar monitor with the nearby Sun Sensor, which detects visible light.)

Combining the XRS surface measurements with the solar monitor's record of the flux from the Sun allows scientists to accurately reconstruct the major element chemistry of Mercury's crust, thus allowing a peek into Mercury's past and providing information on how the planet evolved.

Other spacecraft activities last week included sealing up thermal insulation blankets and adding thermal mass to sensitive items - such as the Sun Sensors, battery, and Radio Frequency (RF) converter and amplifier - that will absorb heat during the short time the spacecraft is exposed to heat from Mercury. The extra mass keeps these items from getting too hot, too quickly.

The hose snaking across the floor in the image is the air duct that keeps MESSENGER's battery cool.

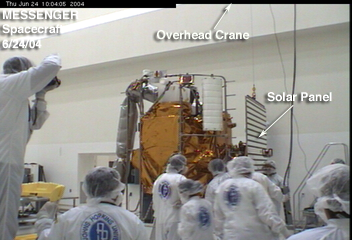

On Again (June 11, 2004)

Many members of the MESSENGER team are back in Florida, preparing the spacecraft for the July 30 - August 13 launch opportunity.

In this week's image, MESSENGER is perched on the “elephant stand” while an overhead crane is used to guide the nickel-hydrogen (Ni-H) flight battery into place. From this vantage point you can see the outer row of 11 individual cells; they look like upside down 1-liter soda bottles. The spacecraft has been running on the spare battery since last November, except for a short period in March when the flight battery was installed, then removed when launch was shifted to no earlier than July 30. Similar to car batteries, spacecraft batteries have limited lifetimes, so the flight battery is reserved until final launch preparations commence.

Click here for large and small time-lapse movies of the battery installation.

Over the coming weeks MESSENGER's instruments will be powered up and tested, its flight radiator and solar panels installed, insulation blankets adjusted and full up simulations run. MESSENGER is scheduled to leave the Astrotech processing facility for mating with its Delta II launch vehicle on July 16.

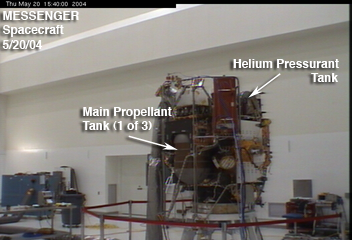

Awaiting the Big Push (June 3, 2004)

With MESSENGER in the late testing stages, launch preparations will soon begin. A few days before MESSENGER is mated to the upper stage of the Delta II launch vehicle, the team will fill the spacecraft's propellant and pressurant tanks.

Like many NASA deep-space missions requiring a lot of maneuvering capability, the MESSENGER spacecraft sports a bipropellant main engine, which, like an automobile engine, needs fuel and an oxidizer to run. Automobiles use gasoline (or diesel) as fuel; the oxidizer is simply oxygen from the atmosphere. Since MESSENGER will be working in the vacuum of space, it needs to carry its own oxidizer (in this case, nitrogen tetroxide) to combine with its hydrazine fuel. Hydrazine is a clear liquid that smells like ammonia and ignites when it meets the right oxidizer, making for a rather simple motor design. Once the fuel and oxidizer are sprayed into the engine nozzle in proper proportions - you have ignition! No spark plugs or other devices are needed to keep the engine running.

Hydrazine is also the lone propellant for the 16 smaller thrusters that help steady the spacecraft. No oxidizer is used in the thrusters so there is no combustion; the fuel sprays out over a heated material (a “catalyst”) that causes it to break apart into nitrogen and hydrogen gas, moving the spacecraft in the direction opposite to where the thruster is pointed. (This is a practical application of Sir Isaac Newton's Third Law of Motion: “For every action there is an equal and opposite reaction.”) To simplify the spacecraft design the MESSENGER team taps off the main hydrazine tanks to run the small thrusters, thus avoiding the need for yet another tank for yet another fuel.

MESSENGER carries 595 kilograms (more than half a ton) of propellant; this includes 97 kilograms (214 pounds) of hydrazine for control and 269 kilograms (593 pounds) to burn with the 229 kilograms (505 pounds) of nitrogen tetroxide in the high-performance “biprop” mode. Helium (2.25 kilograms, or 5 pounds) is used to maintain pressure in the fuel and oxidizer lines. The hydrazine is stored in two large, custom-designed titanium tanks and the oxidizer in a third, similar tank. A smaller tank holds the helium, and an extra supply of hydrazine is carried in a small auxiliary tank.

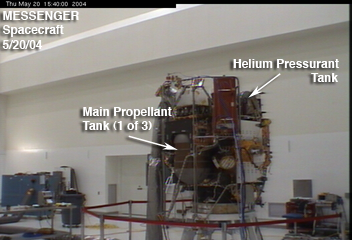

Taking Commands (May 21, 2004)

While MESSENGER sits quietly in the Astrotech Space Operations facility, there is a flurry of activity back in the Mission Operations Center at the Applied Physics Laboratory, where the MESSENGER team is testing and finalizing spacecraft and ground-support software. A spacecraft needs well-understood software onboard its computer and on the ground, in the spacecraft simulator. The simulator is a key to mission success - to safeguard MESSENGER from an errant instruction all command loads are first run through the simulator.

As computer users know, it is easy to make one small mistake, such as a misplaced comma or a wrong sign (like a “+” instead of a “-”). In everyday situations such a mistake simply causes a program error; the user corrects the offending command and moves on. In the unforgiving space environment a wrong sign could (for example) turn MESSENGER's solar panels away from the Sun, resulting in an onboard emergency.

MESSENGER has several layers of protection to prevent such an occurrence. Command “scripts” are carefully prepared and reviewed even before they're run through the simulator. Errors caught in the simulator are corrected and re-tested. If a mistake were to sneak through and be executed by MESSENGER during flight, the onboard autonomy software would detect the error, reorient the spacecraft or take other action to keep MESSENGER safe, send back a “What's up with that command?” message to controllers, and await further instructions from Earth.

In this week's Webcam frame MESSENGER is roped off in its clean room at Astrotech, near Kennedy Space Center, Florida. The air duct keeps MESSENGER's battery cool and the red cover protects the phased array antenna until launch. In June, activities on and around the spacecraft will pick up as final preparations for MESSENGER's July 30-August 13 launch opportunity begin.

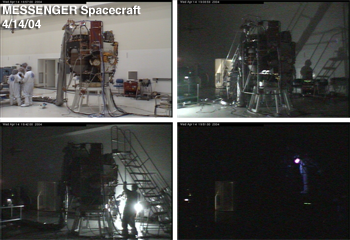

Monthly Cleaning (May 7, 2004)

Keeping MESSENGER clean might not be glamorous work, but it's an important job. Despite the strict measures to keep dust out of the spacecraft assembly and testing areas, some particles do get on MESSENGER. So, about every month, team members roll up their sleeves and clean!

In the upper left section of the above Webcam image, engineers develop a strategy to clean the spacecraft efficiently and safely - deciding who will do what, where to place the ladders, and in what order the surfaces should be cleaned. At top right the team checks if the room is dark enough with only the emergency lights on. (This seems silly at first: who can clean in the dark? But a great way to find dirt is to inspect the spacecraft with a black light.) At lower left, the lights are back on as the team positions ladders and prepares to start cleaning. At lower right, the team members clean MESSENGER's top deck, guided by the handheld black light.

Four people take part: one holding the black light on top of one ladder; another vacuuming on the top of a second ladder; and two others holding ladders and making sure the entire operation is safe for the spacecraft and personnel. After cleaning is complete, the team applies special tape to areas of the spacecraft, lifts it off, and then takes it to a microscope to count the particles. If the number of particles exceeds “clean” limits, the spacecraft is cleaned and checked again. The spacecraft must be cleaner than an operating room to ensure that it will work properly.

Undercover Operations (April 23, 2004)

Watch the Webcam these days and things might look a bit slow around MESSENGER -- but the spacecraft's insides are hard at work! Most of the activity is taking place in the MESSENGER Mission Operations Center at the Johns Hopkins University Applied Physics Lab, where for the next several weeks the team is running autonomy tests and mission simulations on the actual spacecraft. The autonomy tests verify MESSENGER's ability to operate on its own when not in contact with Earth. The mission simulations put MESSENGER (and its operators) through key activities such as the launch sequence, orbit maneuvers, even responses to potential anomalies. The APL team in Maryland stays connected to MESSENGER in Florida through a NASA computer network.

In this week's image, two MESSENGER team members inspect wiring under the spacecraft's thermal blankets on April 9. Most of the “hands on” activity has slowed down during the simulations and autonomy tests, but will pick up later this spring when engineers re-install the sunshade, thermal blankets and solar panels; load fuel into MESSENGER's tanks and conduct spin-balance tests; and attach the spacecraft to the upper stage of its Delta II launch vehicle.

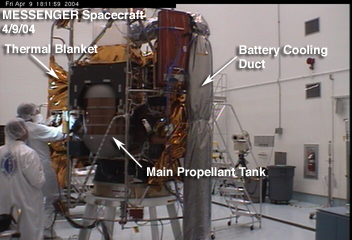

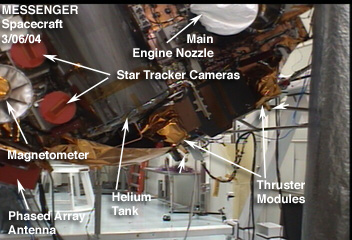

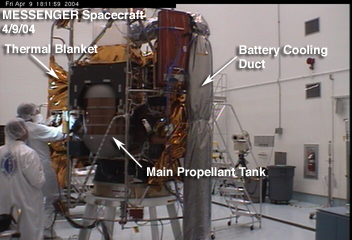

The Layered Look (April 9, 2004)

The MESSENGER team's largest engineering challenge was designing a spacecraft that could work both near Earth and less than 0.4 astronomical units (AU) from the Sun. (One AU is the average distance from the Sun to the Earth, about 150 million kilometers or 93 million miles.)

This image beautifully illustrates the multilayered approach the team devised to fend off the excess heat while the spacecraft is near Mercury, and yet still allow the spacecraft to remain warm when closer to home. The main layer of protection is the ceramic-fabric sunshade, which serves as a giant parasol, ensuring that the spacecraft always keeps its cool while near the Sun. During the initial stages of MESSENGER's long voyage to Mercury the spacecraft will fly backward – the sunshade side will be turned away from the Sun to allow the delicate electronics to remain at a comfortable temperature while basking in the relatively benign lighting conditions near Earth.

In this view, the sunshade has been temporarily removed to allow engineers ready access to MESSENGER's thermal blankets; here a blanket has been folded up, revealing one of the three main propellant tanks. The thermal blankets serve as MESSENGER's second line of defense against the intense solar radiation and the heat reflecting from the surface of Mercury. On the front of the spacecraft they limit the incoming heat; on the rest of MESSENGER they will keep components warm during the cruise to Mercury and the portion of each Mercury orbit when the spacecraft is away from the sunlit (hot) side of the planet.

The blankets are made of many layers (about 20) of aluminized Kapton. The layers are kept from touching each other by embossed bumps. This design almost eliminates conductive heat transfer, the process in which heat flows through a solid form. Heat stays in the spacecraft when MESSENGER is near the Earth, but heat can't get in when MESSENGER is near the Sun.

Working with other parts of MESSENGER's guidance and control system, the Digital Solar Attitude Detectors (or Sun sensors) will help keep the sunshade pointed at the Sun. The solar arrays also pivot, yet another strategy to protect the spacecraft from overheating.

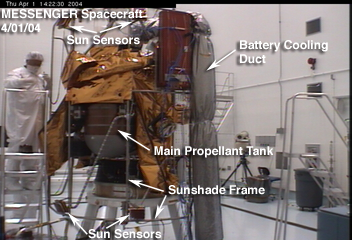

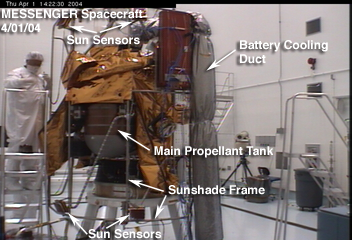

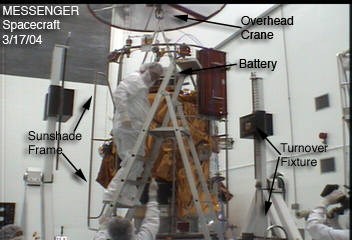

On and Off (April 2, 2004)

With last week's announcement that MESSENGER will launch later this summer, the spacecraft team in Florida had to demonstrate some flexibility. On March 17, engineers installed the flight battery – typically a milestone toward launch. In this Webcam frame the 24.5-kilogram (54-pound) flight battery is settled into position with an overhead crane in the Astrotech Space Operations facility near Cape Canaveral. All batteries have a limited lifetime and thus, flight batteries are only installed shortly before launch to maximize their usable time in space. A spare battery had provided MESSENGER with power since last November.

With the change in launch date, the flight battery came off early this week, to be reinstalled closer to July 30.

A short time-lapse movie (large or small version) shows the 90-minute installation. MESSENGER is back on the familiar turnover fixture to enable easy access to all parts of the spacecraft. The battery is located under a temporary white cover, installed just before the spacecraft is returned to an upright and locked position. Note that the sunshade blanket has been temporarily removed as adjustments are made to the spacecraft.

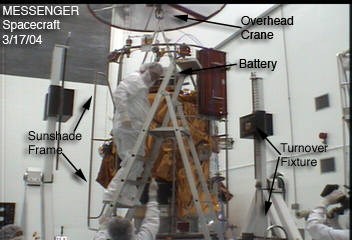

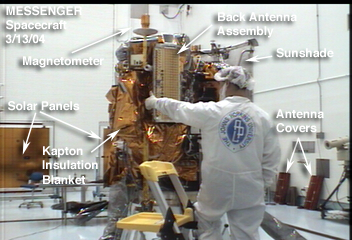

MESSENGER's Lifeline (March 18, 2004)

This week's image shows MESSENGER in Florida undergoing final testing and preparation for launch in May. The spacecraft's solar panels, removed before last week's shipment to the Astrotech Space Operations facility, can be seen on special stands awaiting reinstallation.

The distinctive, temporary red covers have been removed from the two antenna assemblies, allowing an excellent view of the actual antenna systems. Shown here is the back antenna assembly; each assembly is actually four antennas. While at Mercury the low-gain antenna will be used only for spacecraft-to-Earth (downlink) communication at low data rates, while the phased array antennas will provide downlink capability at higher data rates (averaging 9 kilobits per second). The fanbeam actually serves as two antennas, providing both uplink and downlink at moderate data rates (523 bits per second, for downlink).

Over the course of the orbit at Mercury MESSENGER should return at least 78 gigabits of compressed science data, enabling scientists to unravel the origin and evolution of this mysterious planet.

Remaining tasks before launch include final alignment of spacecraft components and scientific instruments, fueling, spin balancing and mating to the Delta II rocket's third stage.

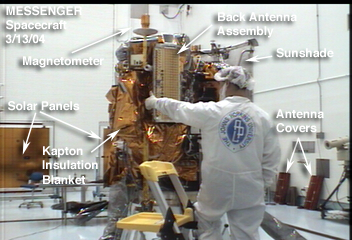

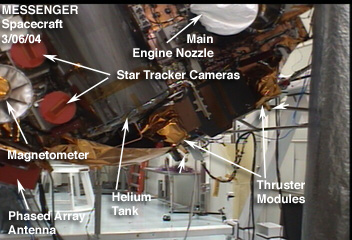

Another Big Move! (March 12, 2004)

This close-up view of MESSENGER's “top” is the last Webcam image taken before the spacecraft was loaded on a truck at NASA Goddard Space Flight Center in Maryland for shipment to the Astrotech Space Operations Facility in Florida, near Kennedy Space Center.

Half of the Magnetometer sensor can be seen under its gold-colored Kapton shield, surrounded by a miniature sunshade that protects it from the extreme solar heat at the end of its boom. The star tracker cameras sport special dust covers (red circles) to keep particles from landing on the optics. These covers – as well as the white elasticized “hat” cover over the main engine nozzle – will be removed shortly before launch.

This image also provides a great view of two modules containing five-pound and one-pound thrusters. The small, unlabeled arrows indicate the nozzles for each one-pound thruster; the five-pound nozzles, with protective red caps, are off to the sides of each “box.” MESSENGER uses helium as pressurant, an inert gas that makes sure the fuel lines are properly pressurized for each critical burn of the main engine.

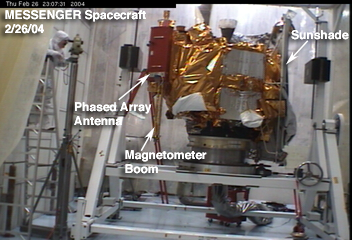

Out of the Oven (March 5, 2004)

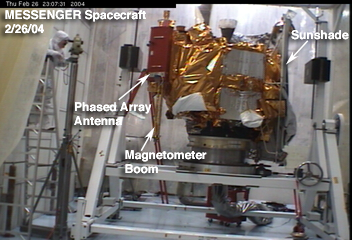

MESSENGER is now well done! The spacecraft is out of the thermal vacuum chamber at NASA Goddard Space Flight Center after five weeks of rigorous environmental tests. Engineers baked the sunshade to about 350 degrees Celsius (662 degrees Fahrenheit) without a problem, and the spacecraft showed it could withstand the wide range of hot and cold temperatures it will face on its journey to and mission around Mercury.

This week's image, taken from the February 26 Webcam movie (small or large version), shows MESSENGER just after it was removed from the thermal vacuum chamber. The spacecraft currently sits in the “Big Tent” at Goddard, a temporary 43- by 13-foot clean room just outside the chamber. The engineer on the ladder is checking the alignment of key components, making sure everything stayed in place during the tests and a crane-lifted move out of the chamber.

Next week MESSENGER begins its trip to Mercury in the back of an air-conditioned semi-trailer; first stop Kennedy Space Center/Cape Canaveral Air Force Station, Fla. After final checkouts and being attached to its Delta II rocket, MESSENGER is scheduled to lift off during a 12-day launch period that opens May 11.

Home Stretch (February 23, 2004)

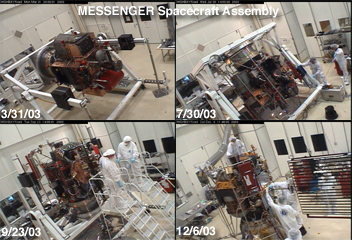

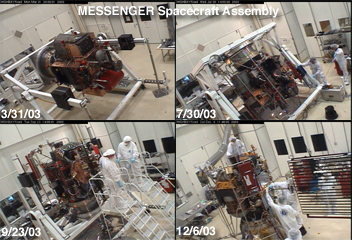

Assembly of the MESSENGER spacecraft started early in 2003 when the integrated structure and propulsion system was delivered to the Applied Physics Laboratory from Aerojet. Since then the spacecraft has gradually taken shape, a process chronicled through the live MESSENGER Webcam and weekly images.We've compressed the nine-month assembly period at APL into various movies, compiled from one to several Webcam frames per day. Visit the daily Webcam movie page and scroll to the bottom boxes, marked “Time Lapse Movie.”

Highlights from last summer include installation of the sunshade frame and onboard computer, and an extensive check of the propulsion system. Most of MESSENGER's science instruments were installed by the end of summer – a key milestone since MESSENGER is a scientific mission above all else.

Through fall the team focused on testing the spacecraft and its installed components. In late October the team installed the last electronics box – and that's when MESSENGER came alive, in that it could respond to commands from its operators! After installation of the solar panels you could imagine MESSENGER on its way to Mercury.

While the latest Webcam views haven't been as exciting, the situation will change shortly – the spacecraft is set to be removed from the thermal-vacuum chamber this week, having passed the battery of hot-and-cold cycling tests that prepare it for the space environment. Final tweaks to the spacecraft will be performed over the following two weeks, and then MESSENGER is headed to Kennedy Space Center/Cape Canaveral for final launch preparations.

The Camera Takes Aim (February 11, 2004)

MESSENGER's camera takes over for the Webcam in this week's image, snapping the above photo during recent instrument alignment checks at NASA's Goddard Space Flight Center. Taken by the Mercury Dual Imaging System's wide-angle camera, the picture shows an engineer using a theodolite – an instrumented telescope used to measure angles – to check the camera's bore sight. This alignment test shows the team exactly where the camera is pointing in relation to the spacecraft's three directional axes.

The picture appears blurry because the wide-angle camera is designed to focus on objects at least 200 kilometers (124 miles) away. The theodolite projects an illuminated cruciform – the white crosshairs in the center of the image – and since its optics make the cruciform appear far away, the crosshairs are in focus when viewed by the wide-angle camera. (If you look closely you can also see a small-but-sharper image of the engineer in the telescope's eyepiece.)

Careful alignment of each MESSENGER instrument is crucial for planning future science observations, but operators will also use the camera for navigation during MESSENGER's flight. In particular, when MESSENGER prepares to enter orbit about Mercury, the navigation team will take distant images of the planet and starry background to refine the spacecraft's exact position in space – knowledge key to pointing the spacecraft correctly during critical engine burns.

Click here to see the image at full resolution.

MESSENGER's Heartbeat (February 6, 2004)

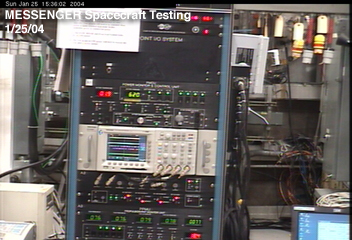

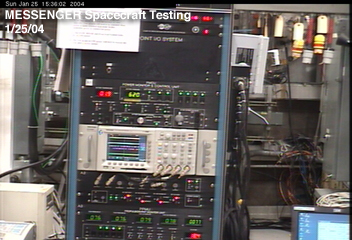

MESSENGER is now ensconced in the thermal vacuum chamber at NASA Goddard Space Flight Center. There are no windows in the chamber so our only way of observing and communicating with the spacecraft is through specialized test equipment, seen in this week's Webcam image.

The top panel (with red and green numbers) is the Power Monitor Control Unit that gives continuous information regarding the spacecraft's power system. These days MESSENGER gets its power from the flight spare battery, supported by a simulator that duplicates the voltage and current MESSENGER will get from its solar panels in space.

Just below the power monitor is an oscilloscope, which displays the transmission rate of commands sent to and data coming back from the spacecraft. Below that, with the green and red lights, is the Spacecraft Signal Distribution Unit, which distributes data between MESSENGER and various pieces of ground equipment supporting the spacecraft.

The lowest panel is the PAF/Propulsion Monitor Unit, which monitors pressure in the propellant tanks (marked by five green numbers across the top) and signals from the Payload Attach Fitting, a metal ring that will connect MESSENGER to its launch vehicle.

The MESSENGER team constantly monitors these vital signs to check that the spacecraft is healthy and operating correctly. The team will use this mode of operating right up until liftoff -- after that, operators will communicate with MESSENGER through NASA's Deep Space Network of antennas."

>